OUR HISTORY

A fifth generation company

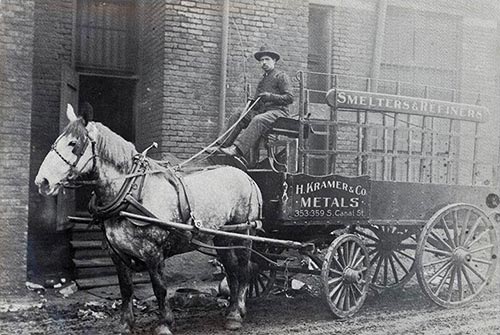

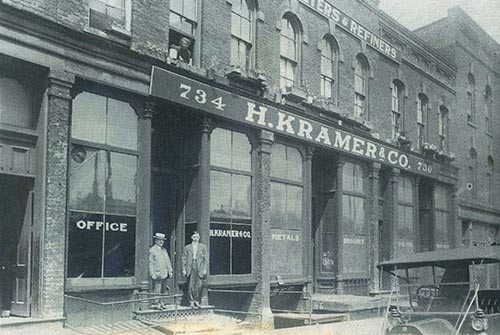

As the vast physical and technological growth of American industry that began with the Industrial Revolution steamrolled into the 1880’s, a young salesman observed a growing need and envisioned a solution. Henry Kramer knew that the basis for the Industrial Revolution was the manufacture of a quality product on a mass production basis. He saw the troubles that foundries were encountering due to use of scrap.

He theorized that if he collected metal in sufficient quantities it would be economically feasible to reprocess it, using quality control methods. Henry Kramer felt that eventually the processing would surpass scrap and virgin metal, at a lower cost.

H. Kramer & Co. and the Brass & Bronze Ingot Industry were born. The company grew rapidly and is still a driving force in what is now a mature industry. Our products are manufactured under exacting methods to conform to a wide range of specifications including A.S.T.M., S.A.E., C.D.A and The Department of Defense.

We are a fifth generation family owned business. We are, above all, a “people company”. Our success is directly traceable to the care and consideration we give to our human resources. Management is dedicated to the health and safety of every Kramer employee. Our management style is hands-on and our executives are readily accessible and actively involved in all phases of the business.